Engineering

Stationary platforms

Marginal oilfields

Floating production systems

Subsea pipelines

Subsea production systems and products

Oil and gas fields integrity management

The Company has established the preliminary design and technical support system for conventional jacket platforms.

The Company has made breakthroughs in new technology areas such as the design of super-long piles, slide-launching technology, float-over design technology, large deep-water oil and gas fields development technology, technology for prolong service life through impressed current cathodic protection, development and application of high-efficiency T-anodes, and applied the same in production projects, achieving good economic benefits.

The Company has undertaken the first international EPCI project (in Thailand) in the real sense, refined its capacity from multiple perspectives including safety management, scope/change management and schedule management, and made certain breakthroughs in its international project management capacity.

Based on the characteristics of Bohai Sea and the South China Sea, the Company has been conducting researches on two typical marginal oilfield development modes, namely, dependable unmanned minim facility platform and undependable multi-purpose production facility, and has established a special work team with its Tianjin Branch.

For mooring system design technology, the successful completion of “HAIYANG SHIYOU 111” FPSO mooring system replacement project marks the Company’s success in breaking up the monopoly of foreign technologies.

For semi-submersible platform design technology, the Company has expanded its capacity from conceptual design and service life prolongation design to detailed design.

For tension leg platform design technology, the Company has completed the FEED of TLP and basically acquired the complete methodology for design of deep-water floating TLPs.

The Company has made new technological breakthroughs in various areas, such as the use of international codes, high temperature high pressure pipeline buckling, aerial crossing analysis techniques, selection of pipe materials, route selection, composite pipe, flexible hose and jumper hose, which have further consolidated its position as a domestic leader.

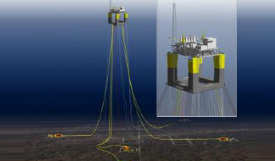

The Company has the capacity to design dee-water subsea production systems and products. The Company has delivered more than 30 projects of subsea systems and products, made breakthroughs from zero capacity to developed capacity in many areas, and successfully forged its path to the subsea systems and products design market.

The Company has the capacity to design subsea production systems for service in 1500 m deep waters.

The Company has the capacity to design various subsea equipment for service in 1500 m deep waters, such as PLET, PLEM, ILM, subsea template, subsea manifold and SUTA, and has made periodic progress in the research and development of critical subsea equipment including subsea connector, subsea distribution unit, subsea separator, subsea control module, etc.

The Company has made great technological breakthroughs in various areas, such as jacket structure, subsea pipe structure, single-point mooring system and FPSO monitoring. Relying on the many years of experience in project design and evaluation, COOEC Engineering Company has secured a domestic dominant position in terms of technical strength, especially in the areas of deep-water jacket platform structural integrity and subsea pipeline integrity.